Water Jet Services

Why Water Jet Cutting?

It's simple. Abrasive water jet technology offers your shop increased flexibility and value, and complements other cutting technologies including EDM and laser. OMAX is the only water jet company that designs and produces its own pump, machine controller, software, and tables. Full system integration from a single source ensures smooth operation, customer satisfaction, and protection for your investment. Whether you're cutting metal or stone, nearly every shop can benefit from abrasive water jet technology.

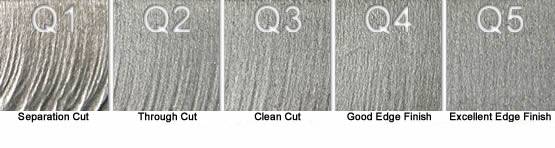

Cutting Quality: "Q5" Edge Finish - 2.8 RMS surface finish

Materials Cut by Water Jets

OMAX JetMachining Centers handle a wide variety of different materials and applications. The OMAX abrasive water jet machine has the ability to cut virtually any material, such as marble, granite, glass, tile, stone, as well as metals such as aluminum, tool steel, titanium, carbon fiber, and composites.

|

Exotic Alloys OMAX water jet cutting machines successfully machine a wide variety of exotic alloys including Inconel and titanium. |

|

|

Glass OMAX variable water jet cutting pressures enable OMAX water jet cutting machines to cut glass quickly and precisely and avoid problems usually associated with machining brittle materials. |

|

|

Rubber water jet-only nozzles cut rubber cleanly and faster than conventional cutting machines. |

|

|

Stone Abrasive water jet cutting uses low-pressure piercing to successfully cut stone. |

|

|

Wood OMAX abrasive water jet cutting machines cut metals, composites, glass, ceramics and more! Do more jobs with higher precision and quality in less time! |

Typical Users / Industries Served

An increasing number of Original Equipment Manufacturers are using OMAX® JetMachining® systems to produce components for their own manufactured products. Many of these manufacturers feel that the speed and flexibility of the OMAX system provides them with a competitive advantage in their industries. The following list provides a general summary of representative uses of the OMAX system by OEMs.

OMAX abrasive water jets not only have the power to revolutionize your machining process, they do also grant you the flexibility to service a variety of industries. From medical to energy to defense and everything in between, OMAX helps you define what's possible in manufacturing.

Industries Served:

• Aerospace |

• Architecture |